SALT LAKE CITY BREWERY & RESTAURANT

Quick Restaurant Menus

Downtown Salt Lake City

254 South 200 West

Salt Lake City, UT 84101

801-521-7446

Fashion Place Mall

6227 South State

Murray, UT 84107

801-262-2337

Park City Junction

1640 W. Redstone Center

Park City, UT 84098

435-575-0295

Great People - Delicious Food - Award Winning Craft Beer

Follow the @redrockbrewing on Instagram for daily updates, brewpub specials and beer release announcements.

What's New at Red Rock Brewing

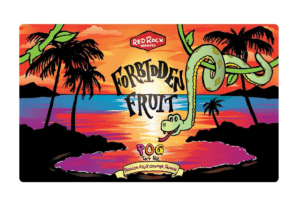

Forbidden Fruit Series – P.O.G.

The history of P.O.G. began in the 1970’s, when Haleakala Dairy on the island of Maui first created a vibrant juice blend of passionfruit, orange and guava. This trio of tropical delights quickly became one of the most popular drinks on the Hawaiian Islands. It’s no surprise that this tangy fruit combination blends perfectly with…

Read More Why So Serious?

Sports. They bring out the best in us. They bring out the worst in us. In a little over 48 hours, someone’s day will be ruined while another jumps for joy. People take sports so seriously. But why? Red Rock’s newest IPA poses more questions than answers. What we do know is this: It’s an…

Read More Nanu Nanu

Alright earthlings, hold on to your spacesuits. Nanu Nanu Hazy Double IPA has been released. Brewed with Vic Secret, Sabro, Citra, and Mosaic, Nanu Nanu has us marveling at a rainbow of hop flavors and aromas! Imagine relaxing in a hammock drinking a pina colada in the middle of a forest. Creamy, dreamy notes of…

Read More Wood Fired Brie Toast

There’s a symphony of flavors in the Wood-Fired Brie Toast at Red Rock Downtown Restaurant & Brew Pub! Pear, grapes, pistachios, and fried sage with a drizzle of balsamic reduction accompany soft, creamy brie over a rustic baguette. Pair with a bottle of Marvella Belgian-style tripel for the perfect opening act to a fabulous meal…

Read More Marvella Belgian Style Tripel

Have you met Marvella? The alluring scent and elegant flavors of our Belgian Tripel feel like a loving caress of the senses. Like a first kiss, soft and lingering, each sip draws you in until you fall head over heels. If you’ve yet to unravel the mystery of Marvella, welcome to her secret garden where…

Read More Beer Loves Chocolate

Beer loves chocolate, and chocolate loves beer! These two really do bring out the best in each other. Beer has many flavors that play well with the tasting notes in chocolate. Hops, malt, and yeast, the main flavor contributors in beer, can express elements of fruit, flowers and herbs, spices, caramel, coffee, and more.…

Read More